Are you wondering how to grease your Steel Green machine? Find out by watching the video below, featuring Kodi Quinlisk, or read on to find out how.

Our machines have a total of five different grease fittings. A grease fitting is under each front wheel, on the side of each front caster, and underneath the machine on the tensioner arm.

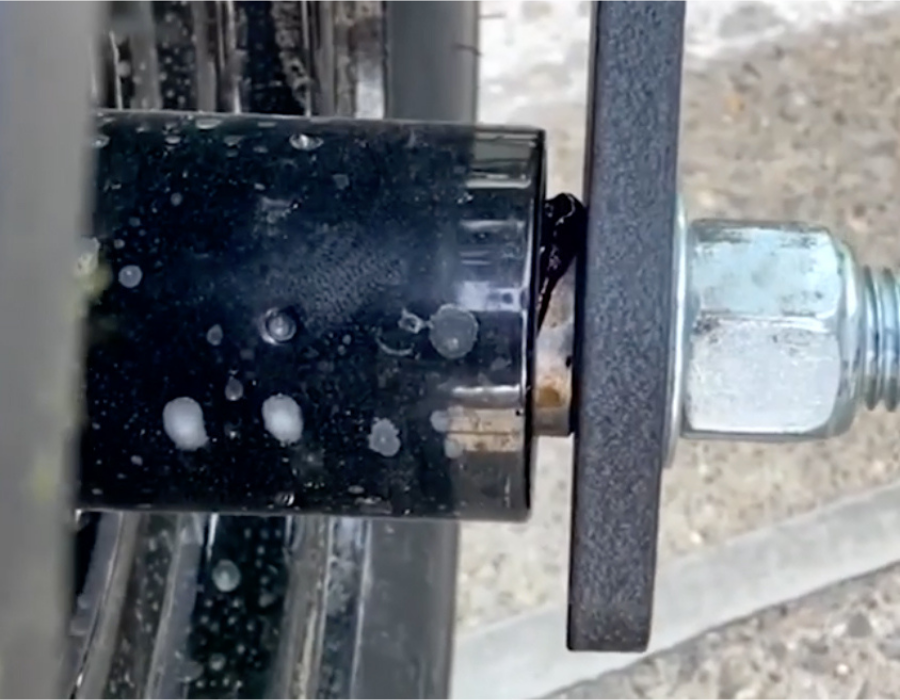

Start with the grease fittings on the front wheels (You’ll want to have a grease gun that is rated for bearings). Put your grease gun on one of the front wheel grease fittings. As you’re greasing it, you’re going to want to watch the gap on both sides of the tire for grease coming out.

This can take multiple pumps. Here, we see the grease beginning to come out. Once that grease starts to come out, don’t go too much more. You don’t want to damage the seal.

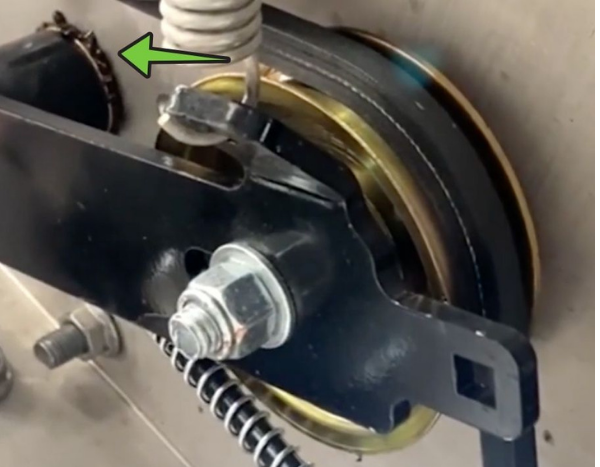

Once you get the front wheels done, grease the fittings on the front castors. When you are greasing the fittings on the front castors, you want to be careful that the caps don’t push off. Over-greasing can cause them to come right off.

There is a hole on the backside of the cap that’s going to any let air out and keep pressure from building.

Here you can see grease coming out. Remember to not over-grease.

After greasing the two front castor fittings, grease the fifth and last fitting on the tensioner arm. It will not take much grease at all, about a half a pump and it starts to come out.

That’s all there is to it. If you have any questions, do not hesitate to reach out to us.

written by

written by